Development of a low Ug pane with 4 chamber Heat-Mirror structure and ec pane for variation of the SHGC-value with an automatic control strategy considering the weather-predictive energy harvesting strategy and the model of glare evaluation

By the principle of the Heat Mirror Technology (=HM), a coated film is implemented in the space between the panes of a windowpane in order to increase heat and sun protection. This does not only save weight, but also enables the window to be used overhead due to its favourable convection behaviour.

Electrochromic (=EC) panes offer numerous advantages over mechanical shading systems, but have high Ug-values compared to currently available insulating glass panes. Current regulations can only control the EC pane automatically to a limited extent. Although good insulating glass panes reduce heat loss, this leads to excessive heating of the room in the case of high solar radiation without built-in blinds or without a high SHGC-value, especially in summer. In addition, the environmental conditions are not sufficiently considered in the design of the insulating glass units, or a targeted, location-specific energy optimisation is not carried out.

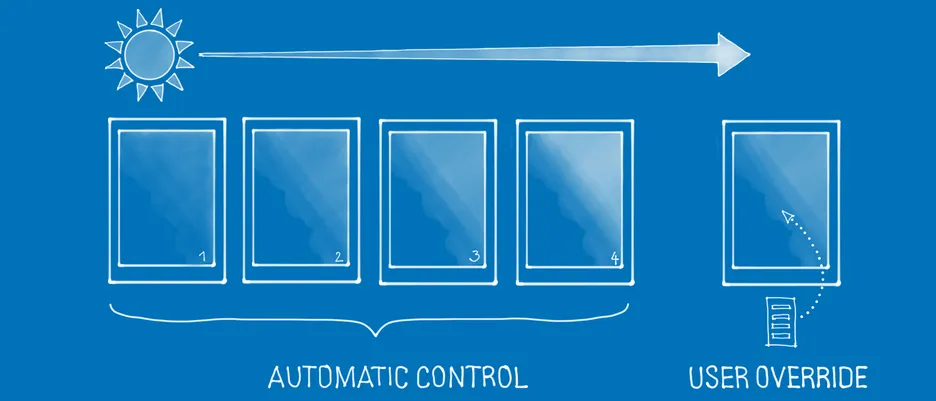

In view of the above-mentioned disadvantages, this R&D project aims to develop a fully integrated EC low-glazed insulating glass with a glare-avoiding, weather-predictive energy harvesting strategy by using irradiation. With the planned structure, an EC glass with a Ug-value of approx. 0.2 W/m²K is to be developed for the first time. The automatic control of the SHGC-value based on the ambient conditions should reduce the energy demand over the year and increase the thermal and visual comfort.