CantiBox

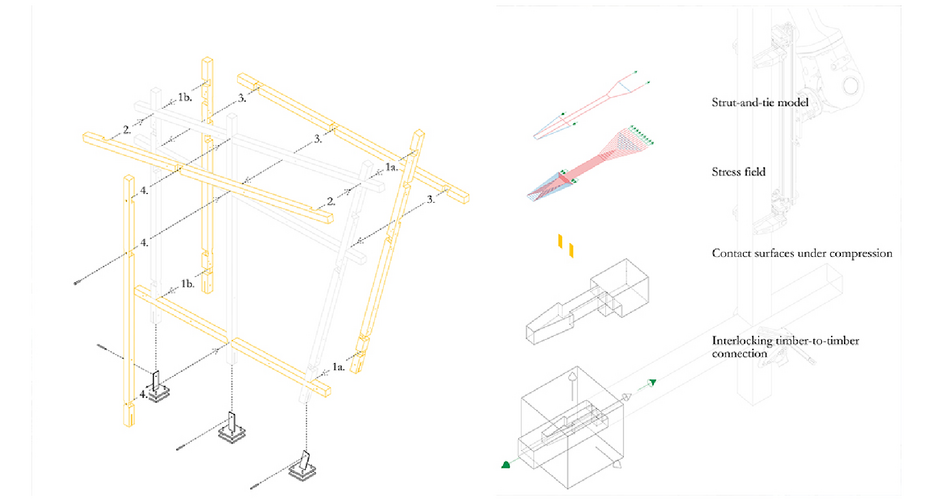

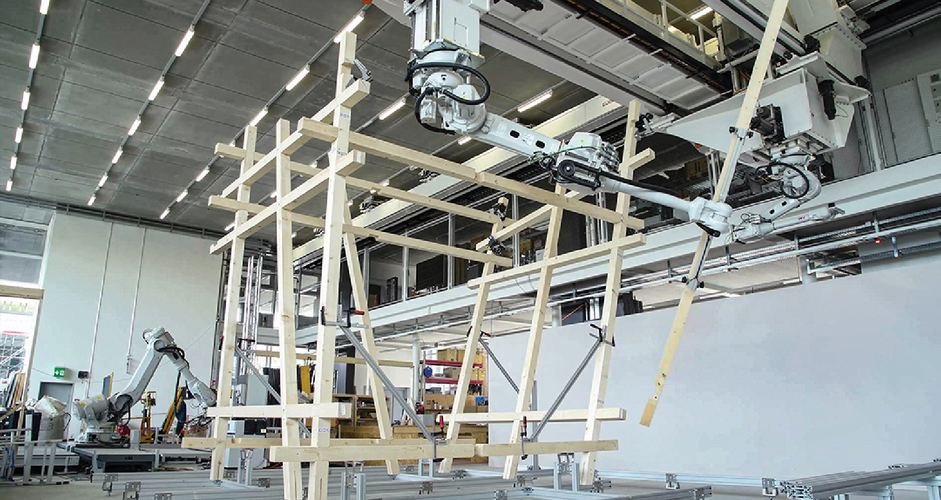

CantiBox was developed as a joint collaboration between ETH Zurich (Chair of Structural Desing and Gramazio & Kohlrer Research), MIT (Digital Strucutres) and Technical University of Munich (Professorship of Strucutral Design). CantiBox is a robotically assembled structure representing a novel application of the design and automatic assembly of interlocking timber-to-timber connections. It is composed of 60 linear elements of solid spruce with a cross-section of 10 by 10 cm interconnected through bespoke half-lap joints. The structure consists of three units of 20 elements each: two lateral boxes sitting on the ground and a cantilevering central box. The interweaving logic of the structure allows the use of exclusively interlocking timber-to-timber connections, with only four external fasteners per unit to prevent disassembly.

Each unit contains 36 customized lap joints that are designed based on the static method of limit analysis, based on plastic theory. In an interlocking connection, forces are transferred between the elements by means of compressed contact areas. The capacity depends on two parameters: the contact surface's size and the associated strength value. The contact surface strength indicates the maximum stress that a surface can withstand, while the strength value is calculated thanks to stress fields and timber yield conditions and then validated through mechanical tests. The capacity of the connection is determined by defining the possible contact areas between the timber elements and their resistances, as well as by transferring the plastic redistribution of the force on the contact surfaces. This approach allows geometric adjustments of each joint according to different loading conditions. The conventional half-lap joint connection is, therefore, customized - whenever necessary - to adapt its capacity to internal stresses.

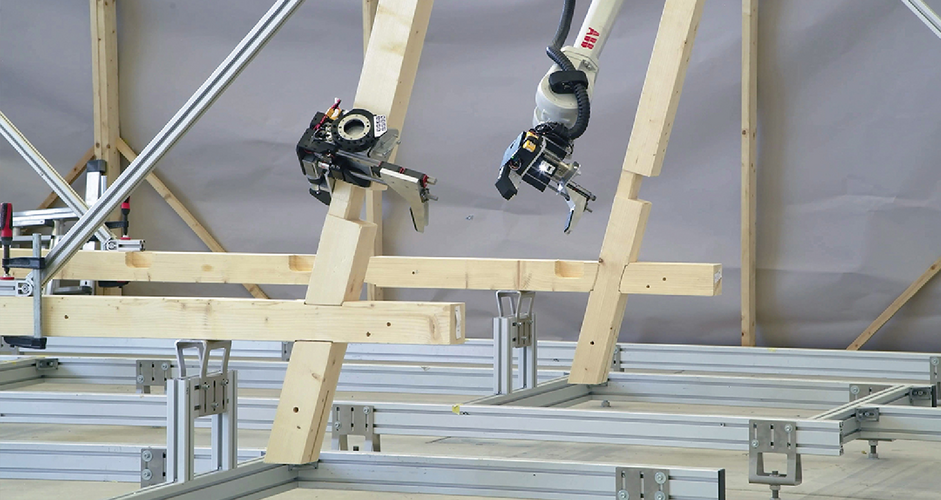

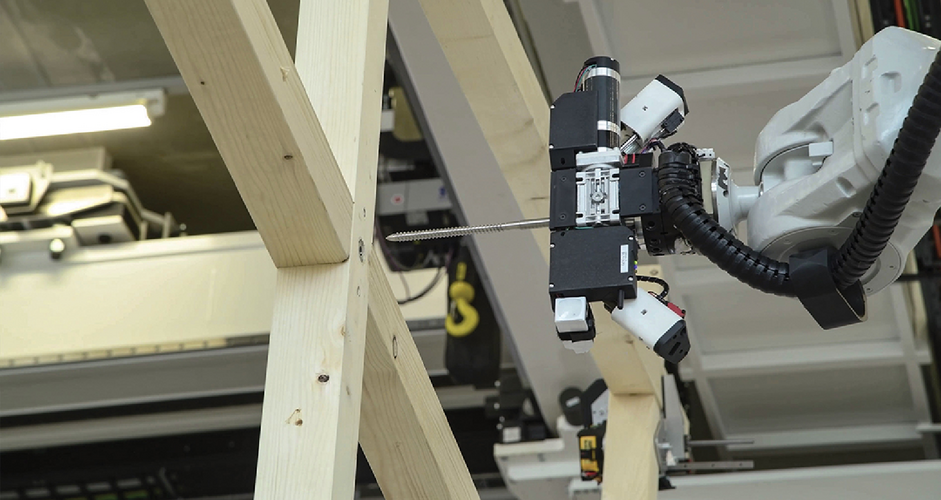

The three units are assembled independently through a fully automatic process, which uses a set of distributed robotic clamps and screwdrivers to operate in collaboration with an industrial robotic arm. This approach enables the automated assembly of bespoke timber structures directly in 3D as opposed to planar sub-assemblies. At the same time, it overcomes well-known challenges in robotic timber joint assembly: large assembly force to overcome friction, simultaneous assembly of multiple joints, as well as to ensure local and global accuracy. To accommodate the bespoke design, the task and motion planning of the robotic process is performed automatically.

CantiBox demonstrates two cutting-edge approaches for jointed timber structures. First is the static method of limit analysis for interlocking timber-to-timber connection design. Second is the use of distributed robotic tools to achieve a fully automatic assembly process. Indeed, each of the three units is directly constructed in space. Both technologies complete a critical knowledge gap that enables bespoke design and construction of spatial timber structures. Their flexibility to accommodate custom design can be witnessed in the use of the interweaving logic to create a reciprocal network.

Project Coordination

Davide Tanadini (Chair of Strucutral Design, ETH Zurich)

Victor Pok Yin Leung (Gramazio & Kohler Research, ETH Zurich)

Yijiang Huang (Digital Structures, MIT)

Design Team

Davide Tanadini (Chair of Structural Design, ETH Zurich)

Giulia Boller (Chair of Structural Design, ETH Zurich)

Prof. Dr. Pierluigi D'Acunto (Professorship of Structural Design, TUM)

Victor Pok Yin Leung (Gramazio & Kohler Research, ETH Zurich)

Yijiang Huang (Digital Structures, MIT)

Collaborators

Dr. Aleksandra Anna Apolinarska, Dr. Lauren Vasey, Gonzalo Casas (Gramazio Kohler Research ETH Zurich)

Prof. Dr. Agatha Koller, Marco Rossi, Luca Steiner (ILT, OST, Rapperswil)

Caelan Garrett (NVIDIA Seattle Robotics Research Lab, USA)

Philippe Fleischmann and Michael Lyrenmann (NCCR Digital Fabrication, ETH Zurich)

Industry Partner

AUER Holzbau

Student Team

Rodrigo Mendoza Diaz, Dario Quaglia, Valentin Ribi, Louis Strologo and Leandro Nahuel Barroso (Chair of Structural Design, ETH Zurich)