I3DCP Bridge

Over the past few decades, the construction industry has undergone significant changes due to the emergence of automation and digitalization. One of the most promising technologies in this regard is 3D concrete printing, which offers numerous advantages over traditional construction methods, including a reduction of materials, waste, and energy, higher degrees of geometric complexity of structural members, and increased automation. However, current additive manufacturing techniques primarily focus on layer-by-layer based 3D printing techniques that are commonly applied in horizontal layers. While layer-by-layer processes feature a set of distinct advantages, there are inherent limitations to them, i.e. a limited ability in geometric complexity such as overhangs, which need additional structural support.

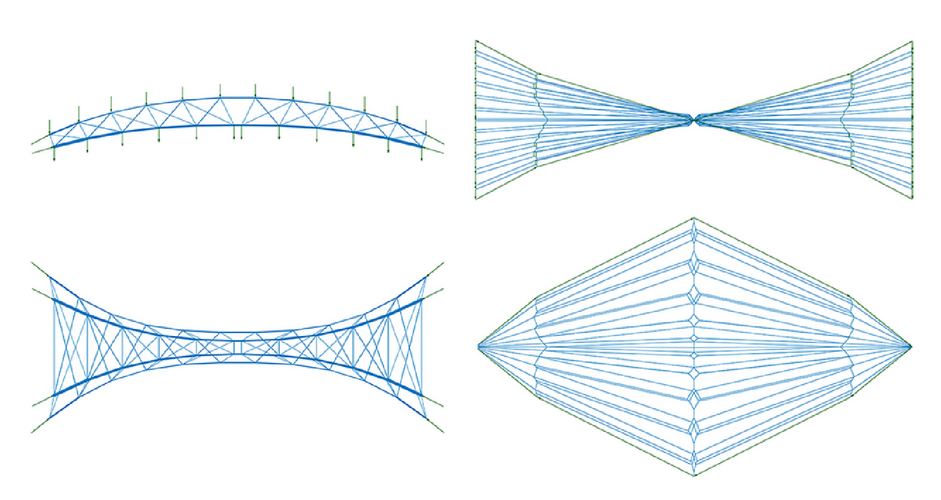

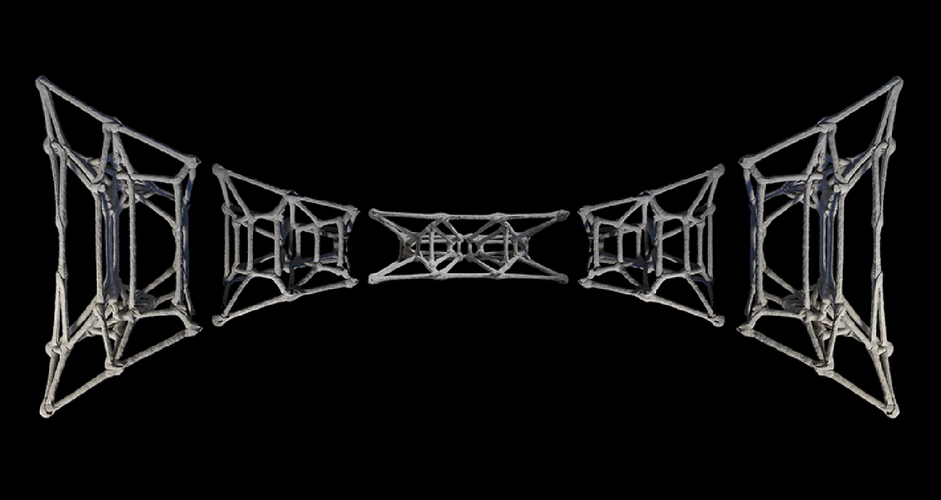

The novel approach of Injection 3D Concrete Printing (I3DCP) has been recently introduced, which challenges the layered build-up and enables more complex spatial printing trajectories. This technology involves the robotic injection of concrete into a non-hardening carrier liquid that supports the printed strands. With this technique, we can create intricate and filigree lightweight structures, which are today completely unknown with concrete as a construction material. Furthermore, the use of I3DCP allows the print path to be aligned with complex spatial stress trajectories that can be treated as strut-and-tie networks in the design phase using equilibrium-based methods such as Vector-based Graphic Statics (VGS). VGS is a geometry-based approach to the analysis and design of structures in static equilibrium that is particularly effective for designing spatially complex, lightweight, and material-efficient structures. VGS uses the form diagram to model the geometry of a structure with its applied loads and the force diagram to represent the equilibrium of the forces applied to the nodes of the structure. By combining VGS and I3DCP, the geometry of the lattice structure can be optimized in the early design phase to meet the static requirements and constraints of the I3DCP manufacturing process. The goal is to make 3D concrete printing more efficient, sustainable, and cost-effective and to explore new possibilities for design and construction that were previously unimaginable.

Project Team

Prof. Dr. Norman Hack, Prof. Dr. Harald Kloft, Yinan Xiao (Institute of Structural Design, Technische Universität Braunschweig)

Prof. Dr. Pierluigi D’Acunto, Dr. Patrick Ole Ohlbrock (Professorship of Structural Design, Technical University of Munich)

Jun.-Prof. Dr. Inka Mai (Professorship of Robot-Assisted Manufacturing of the Built Environment, TU Berlin)

Prof. Dr. Dirk Lowke, Aileen Vandenberg, Ph.D. (Institute of Building Materials, Concrete Construction and Fire Safety, Technische Universität Braunschweig)

Sponsors

Volkswagen Stiftung

Matthäi Stiftung