The Canopy

Project Coordinators

Prof. Dr. Pierluigi D'Acunto (Professorship of Structural Design, TUM)

Dr. Patrick Ole Ohlbrock (Chair of Structural Design, ETH Zürich)

Alessandro Tellini (Raplab, ETH Zürich)

Design Team

Federico Bertagna, Ueli Oskar Brunner, Giulia Boller, Christian Egli, Philippe Hilger, Dr. Patrick Ole Ohlbrock, Prof. Dr. Joseph Schwartz, Davide Tanadini, Shuaizhong Wang, Fabio Meier, Dario Quaglia (Chair of Structural Design, ETH Zürich)

Enrique Corres Sojo, Diego Hernández Fraile, Prof. Dr. Aurelio Muttoni (EPFL Lausanne)

Prof. Dr. Pierluigi D'Acunto (Professorship of Structural Design, TUM)

Collaborator

Marco Bahr (Dr. Schwartz Consulting)

Industry Partner

Fabian Graber (Jakob AG)

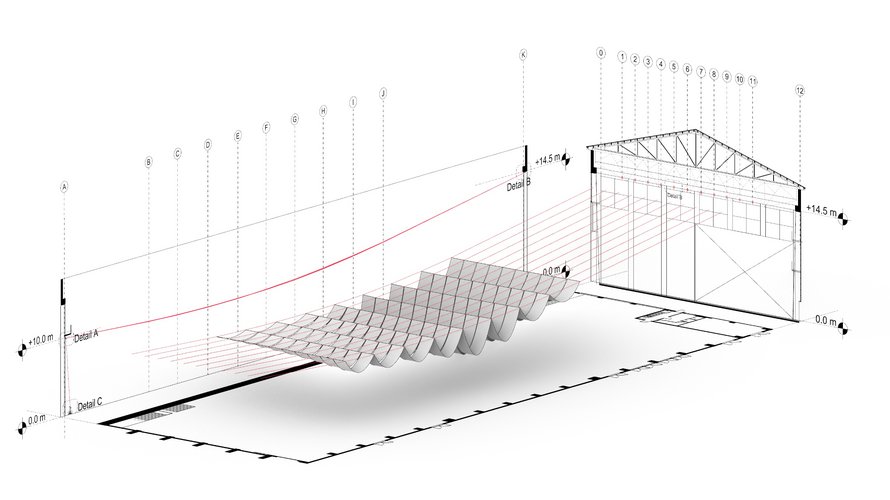

The Canopy is a lightweight installation inside the “Kiesofenhalle”, a 94.5 m by 33.2 m hall located in a former cellulose factory in Attisholz, Switzerland. The project aimed at creating a venue for the 3-day event of the International fib Symposium on “Conceptual Design of Structures”, which was held in September 2021 and hosted more than 150 participants. In conjunction with the conference, an exhibition explored the Swiss contribution to structural design looking at design methods and exemplary projects. Hanging Canopy was used to separate the hall into three distinct areas: an auditorium, an exhibition space and an informal area for the social activities related to the conference.

The Canopy is made of perforated fabric hanging from suspension cables. The project was designed to be as light and simple as possible, to be easily installed on site and to minimize the interference with the existing building. The project refers to the hanging chain’s principle based on the catenary line, as a conceptual design approach that considers spatial as well as structural aspects.

Eleven steel cables with a diameter of 5 mm each are suspended ten metres above the ground and span the hall’s 94.5 m longitudinal length. Their shape was form-found using graphic statics, a vector-based structural design method that allows for simultaneous control of form and forces. Ten fabric strips hang from the steel cables. Their geometry was designed in relation to the structural pattern of the existing building. In fact, the undulation of the hanging elements follows the repartition of the slender reinforced concrete roof trusses that characterize the interior of the existing hall. The final materialisation of the project resembles an abstract cloud floating inside the hall. Thanks to the perforated fabric, the canopy maintains visual continuity with the concrete trusses on the roof of the existing hall.

The correct measurements along the ten textile strips, as well as the accurate marking of the hanging points along the steel cables represented the crucial aspect for the success of the project. A customized measuring machine was designed and built to ensure accuracy in the positioning of the anchoring points along the fabric strips. The hanging connections between the steel cables and the fabric strips were 3D printed. This process retained enough tolerance and allowed for rapid assembly on site.

After anchoring the steel cables to the concrete walls of the existing hall, the fabric strips could be easily attached to the various suspension points along the steel cables. The relative height of the Hanging Canopy was manually controlled by adjusting the tension of each steel cable. The entire construction process took only 8 hours. Thanks to its undulating, multi-layered and translucent appearance, Hanging Canopy works well with different settings and lighting effects inside the existing hall. Despite its ephemeral presence, the project enhances the qualities of the existing building and transforms it to accommodate new functions in a subtle and respectful manner.