Slab Net Zero - Additive in-situ fabrication of cap ceilings

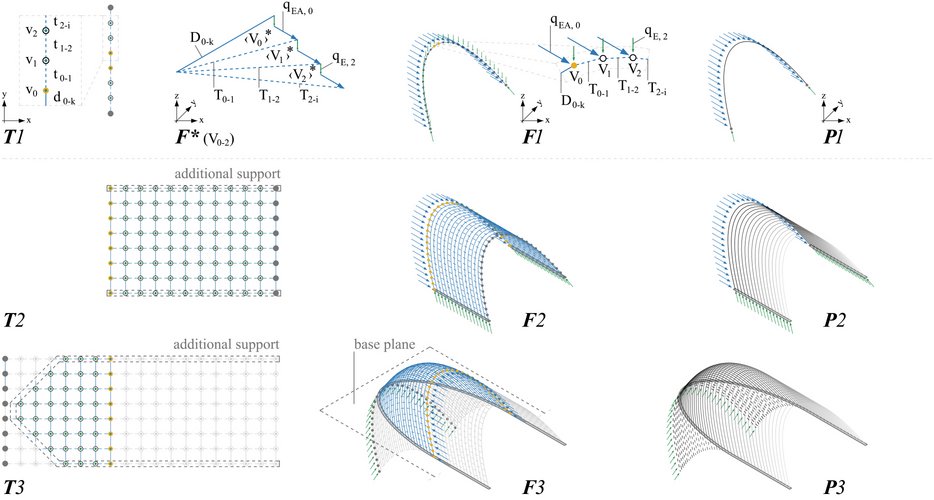

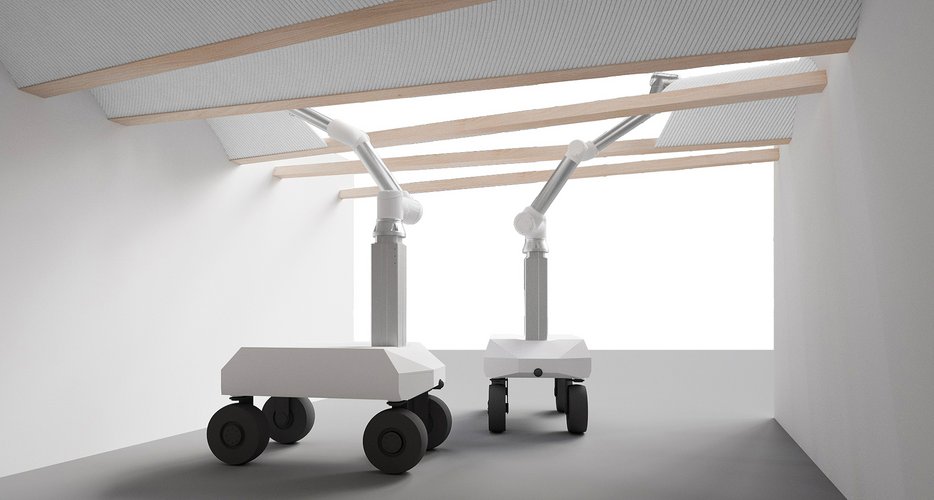

As part of SLAB NET ZERO, experts from the industry are collaborating with chairs from TUM in the fields of Digital Fabrication, Structural Design, Climate Design, and Architecture to make a significant contribution to CO2-neutral construction in the new build sector and drastically reduce the use of concrete. This is achieved through in situ additive manufacturing of ceiling slabs using mobile robots. In non-residential construction (currently about 50% of new construction volume in Germany), there are high demands on floor slabs due to large spans and intensive building technology, which typically require flat concrete slabs with a thickness of 25-30 cm. SLAB ZERO combines the high compressive strength of mineral materials with the geometric freedom of additive manufacturing to explore new innovative solutions for 3D printing resource-efficient and function-integrated ceiling systems directly at construction sites. This essentially results in a structurally optimized vaulted form that substantially minimizes the concrete content. The elimination of steel reinforcement further reduces CO2 emissions, and the shaping of the slabs allows for construction with a mobile 3D printing system without formwork. Additionally, the traditional structure of a reinforced concrete ceiling with a suspended ceiling for building technology is reversed: the solid layer in the form of a printed ceiling slab is directly connected to the space and ensures a pleasant quality of stay through its thermal mass and the possibilities for component activation. The new approaches and methods are experimentally validated through the production of prototypes and test specimens. The goal of this project is to test this new process solution in terms of its practicality and assess how additive manufacturing technology can fundamentally make the way we plan and construct buildings more resource-efficient.

Research Team:

Frederic Chovghi, Prof. Dr. Pierluigi D’Acunto, Professorship of Structural Design, School of Engineering & Design, Technical University of Munich

David Richter, Gido Dielemans, Prof. Dr. Kathrin Dörfler, Professorship of Digital Fabrication, School of Engineering & Design, Technical University of Munich

Benedikt Grimm, Dr. Thomas Kränkel, Centrum Baustoffe und Materialprüfung, Technical University of Munich

Julian Möhring, Tilmann Jarmer, Prof. Florian Nagler, Chair of Architectural Design and Construction, School of Engineering and Design, Technical University of Munich

Ahmad Nouman, David Briels, Prof. Thomas Auer, Chair of Building Technology and Climate Responsive Design, School of Engineering and Design, Technical University of Munich

Industry Partners:

Andreas Haertl, Christ Dieter, David Abele, Abele Engineers

Achim Frank, Christian Braig, Fabian Meyer-Brötz, PERI GmbH

Funding programme:

Zukunft Bau Forschungsförderung, Funding code 10.08.18.7-22.21

Duration:

10.2022 – 03.2025

Related publications:

Chovghi, Frederic; Richter, David; Dörfler, Kathrin; D'Acunto, Pierluigi: Reconsidering the historical cap ceiling: layerwise form-finding of self-supporting vaulted structures for in situ 3D printing. Proceedings of the IASS 2024 Symposium, 2024 more…